Wind Turbine Design

At the heart of any renewable wind power generation system is the Wind Turbine. Wind turbine designs generally comprise of a rotor, a direct current (DC) generator or an alternating current (AC) alternator which is mounted on a tower high above the ground.

So how are wind turbines designed to produce electricity?. In its simplest terms, a wind turbine is the opposite to a house or desktop fan. The fan uses electricity from the mains grid to rotate and circulate the air, making wind. Wind turbine designs on the other hand use the force of the wind to generate electricity. The winds movement spins or rotates the turbines blades, which captures the kinetic energy of the wind and convert this energy into a rotary motion via a shaft to drive a generator and make electricity as shown.

Typical Wind Turbine Generator Design

The image above shows the basic components that go to make up a typical wind turbine design. A wind turbine extracts the kinetic energy from the wind by slowing the wind down, and transferring this energy into the spinning shaft so it is important to have a good design. The available power in the wind that is available for harvesting depends on both the wind speed and the area that is swept by the rotating turbine blades. So the faster the wind speed or the larger the rotor blades the more energy can be extracted from the wind. So we can say that wind turbine power production depends on the interaction between the rotor blades and the wind and it is this interaction that is important for a wind turbine design.

To help improve this interaction and therefore increase efficiency two types of wind turbine design are available. The common horizontal axis and the vertical axis design. The horizontal axis wind turbine design catches more wind so the power output is higher than that of a vertical axis wind turbine design. The disadvantage of the horizontal axis design is that the tower required to support the wind turbine is much higher and the design of the rotor blades has to be much better.

A Typical Wind Turbine Blade Design

The Vertical Axis Turbine or VAWT, is easier to design and maintain but offers lower performance than the horizontal axis types due to the high drag of its simple rotor blade design. Most wind turbines generating electricity today either commercially or domestically are horizontal axis machines so it is these types of wind turbine design we will look at in this wind turbine tutorial.

• The Rotor – This is the main part of a modern wind turbine design that collects the winds energy and transforms it into mechanical power in the form of rotation. The rotor consists of two or more laminated-wood, fibreglass or metal “rotor blades” and a protective hub which rotates (hence its name) around a central axis.

Just like an aeroplane wing, wind turbine blades work by generating lift due to their curved shape. The rotor blades extract part of the kinetic energy from the moving air masses according to the lift principle at a rate determined by the wind speed and the shape of the blades. The net result is a lift force perpendicular to the direction of flow of the air. Then the trick is to design the rotor blade to create the right amount of rotor blade lift and thrust producing optimum deceleration of the air and no more.

Unfortunately the turbines rotor blades do not capture 100% all of the power of the wind as to do so would mean that the air behind the turbines blades would be completely still and therefore not allow any more wind to pass through the blades. The theoretical maximum efficiency that the turbines rotor blades can extract from the wind energy amounts to between 30 and 45% and which is dependant on the following rotor blade variables: Blade Design, Blade Number, Blade Length, Blade Pitch/Angle, Blade Shape, and Blade Materials and Weight to name a few.

• Blade Design – Rotor blade designs operate on either the principle of the lift or drag method for extracting energy from the flowing air masses. The lift blade design employs the same principle that enables aeroplanes, kites and birds to fly producing a lifting force which is perpendicular to the direction of motion. The rotor blade is essentially an aerofoil, or wing similar in shape to an aeroplane wing. As the blade cuts through the air, a wind speed and pressure differential is created between the upper and lower surfaces of the blade.

The pressure at the lower surface is greater and thus acts to “lift” the blade upwards, so we want to make this force as big as possible. When the blades are attached to a central rotational axis, like a wind turbine rotor, this lift is translated into a rotational motion.

Opposing this lifting force is a drag force which is parallel to the direction of motion and causes turbulence around the trailing edge of the blade as it cuts through the air. This turbulence has a braking effect on the blade so we want to make this drag force as small as possible. The combination of lift and drag causes the rotor to spin like a propeller.

Drag designs are used more for vertical wind turbine designs which have large cup or curved shaped blades. The wind literally pushes the blades out of the way which are attached to a central shaft. The advantages of drag designed rotor blades is slower rotational speeds and high torque capabilities making them useful for water pumping and farm machinery power. Lift powered wind turbines having a much higher rotational speed than drag types and therefore are well suited for electricity generation.

• Blade Number – The number of rotor blades a wind turbine design has is generally determined by the aerodynamic efficiency and cost. The ideal wind turbine would have many thin rotor blades but most horizontal axis wind turbine generators have only one, two or three rotor blades. Increasing the number of rotor blades above three gives only a small increase in rotor efficiency but increases its cost, so more than three blades are usually not required but small high spinning multi-bladed turbine generators are available for home use. Generally, the fewer the number of blades, the less material is needed during manufacturing reducing their overall cost and complexity.

Single bladed rotors have a counter balance weight on the opposite side of the rotor but suffer from high material stress and vibration due to their unsmooth rotational motion of the single blade which must move more rapidly to capture same amount of wind energy. Also with single or even double bladed rotors, most of the available air movement and therefore wind power passes through the unswept cross-sectional area of the turbine without interacting with the rotor decreasing their efficiency.

Multi-bladed rotors on the other hand have a smoother rotational operation and lower noise levels. Slower rotational speeds and torque are possible with multi-bladed designs which reduces the stresses in the drive train, resulting in lower gearbox and generator costs. However, wind turbine designs with many blades or very wide blades will be subject to very large forces in very strong winds which is why most wind turbine designs use three rotor blades.

• An Odd or Even Number of Rotor Blades? – A wind turbine design which has an “EVEN” number of rotor blades, 2, 4 or 6, etc, can suffer from stability problems when rotating. This is because each rotor blade has an exact and opposite blade which is located 180o in the opposite direction. As the rotor rotates, the very moment the uppermost blade is pointing vertically upwards (12 o’clock position) the lower most blade is pointing straight down in front of the turbine support tower. The result is that the uppermost blade bends backwards, because it receives the maximum force from the wind, called “thrust loading”, while the lower blade passes into the wind free area directly in front of the supporting tower.

This uneven flexing of the turbines rotor blades (uppermost bent in the wind and the lowermost straight) at each vertical alignment produces unwanted forces on the rotor blades and rotor shaft as the two blades flex back and forth as they rotate. For a small rigid aluminium or steel bladed turbine this may not be a problem unlike longer fibreglass reinforced plastic blades.

A wind turbine design which has an “ODD” number of rotor blades (at least three blades) rotates smoother because the gyroscopic and flexing forces are more evenly balanced across the blades increasing the stability of the turbine. The most common odd bladed wind turbine design is that of the three bladed turbine. The power efficiency of a three bladed rotor is slightly above that of a similar sized two bladed rotor and due to the additional blade they can rotate slower reducing wear and tear and noise.

Also, to avoid turbulence and interaction between the adjoining blades, the spacing between each blade of a multi-bladed design and its rotational speed should be big enough so that one blade will not encounter the disturbed, weaker air flow caused by the previous blade passing the same point just before it. Because of this limitation most odd type wind turbines have a maximum of three blades on their rotors and generally rotate at slower speeds.

Generally, three bladed turbine rotors integrate better into the landscape, are more aesthetically appealing and are more aerodynamically efficient than two bladed designs which contributes to the fact that three bladed wind turbines are more dominate in wind power generation market. Although certain manufacturers produce two and six-blade turbines (for sail boats). Other advantages of odd (three) bladed rotors include smoother operation, less noise and fewer bird strikes which compensate for the disadvantage of the higher material costs. Noise level is not affected significantly by the blade count.

• Rotor Blade Length – Three factors determine how much kinetic energy can be extracted from the wind by a wind turbine: “the density of the air”, “the speed of the wind” and “the area of the rotor”. The density of the air depends upon how far above sea level you are while the wind speed is controlled by the weather. However, we can control the rotational area swept by the rotor blades by increasing their length as the size of the rotor determines the amount of kinetic energy a wind turbine is able to capture from the wind.

The rotor blades rotate around a central bearing forming a perfect circle of 360O as it rotates and as we know from school, the area of a circle is given as: π.r2. So as the swept area of the rotor increases, the area it covers also increases with the square of the radius. Thus, doubling the length of a turbines blades results in an increase of four times its area which allows it to receive four times as much wind energy. However, this greatly increases the size, weight and ultimately the cost of the wind turbine design.

One important aspect of the blade length is the rotational tip-speed of the rotor resulting from the angular velocity. The longer the turbine blade length the faster the rotation of the tip for a given wind speed. Likewise, for a given rotor blade length the higher the wind speed the faster the rotation. So why can we not have a wind turbine design with very longer rotor blades operating in a windy environment producing lots of free electricity from the wind. The answer is that there becomes a point where the length of the rotor blades and the speed velocity of the wind actually reduces the output efficiency of the turbine. This is why many larger wind turbine designs rotate at much slower speeds.

Efficiency is a function of how fast the rotor tip rotates for a given wind speed producing a constant wind speed to tip ratio called the “tip-speed ratio” ( λ ) which is a dimensionless unit used to maximise the rotor efficiency. In other words, “tip-speed ratio” (TSR) is the ratio of the speed of the rotating blade tip in rpm to the speed of the wind in mph, and a good wind turbine design will determine the rotor power for any combination of wind and rotor speed. The larger this ratio, the faster the rotation of the wind turbine rotor at a given wind speed. The shaft speed that the rotor is fixed too is given in revolutions per minute (rpm) and depends on the tip-speed and the diameter of the turbines blades.

A turbines rotational speed is defined as: rpm = wind speed x tip-speed-ratio x 60 / (diameter x π).

If a turbines rotor rotates too slowly, it allows too much wind to pass through undisturbed, and thus does not extract as much as energy as it could. On the other hand, if the rotor blade rotates too quickly, it appears to the wind as one large flat rotating circular disc, which creates large amounts of drag and tip losses slowing the rotor down. Therefore it is important to match the rotational speed of the turbine rotor to a particular wind speed so that the optimum efficiency is obtained. Turbine rotors with fewer blades reach their maximum efficiency at higher tip-speed ratios and generally, three bladed wind turbine designs for electrical generation have a tip speed ratio of between 6 and 8, but will run more smoothly because they have three blades. On the other hand, turbines used for water pumping applications have a lower tip speed ratio of between 1.5 and 2 as they are specially designed for high torque generation at low speeds.

• Rotor Blade Pitch/Angle – fixed design wind turbine rotor blades are generally not straight or flat like aeroplane aerofoil wings, but instead have a small twist and taper along their length from the tip to the root to allow for the different rotational speeds along the blade. This twist allows for the blade to absorb the winds energy when the wind is coming at it from different tangential angles and not just straight-on. A straight or flat rotor blade will stop giving lift and may even stop (stall), if the rotor blade is hit by the wind at different angles, called the “angle of attack” especially if this angle of attack is too steep.

Therefore, to keep the rotor blade seeing an optimum angle of attack increasing lift and efficiency, wind turbine design blades are generally twisted throughout the length of the blade. In addition, this twist in the wind turbine design keeps the rotor blades from spinning too fast in high wind speeds.

However, for very large-scale wind turbine designs used for electrical power generation, this twisting of the blades can make their construction very complicated and expensive, so some other form of aerodynamic control is used to keep the blades angle of attack perfectly aligned with the wind direction.

The aerodynamic power produced by the wind turbine can be controlled by adjusting the pitch angle of the wind turbine in relationship to the angle of attack of the wind as each blade is rotated about its longitudinal axis. Then rotor blades with pitch control can be flatter and more straight but generally these large blades have a similar twist in their geometry but much smaller to optimise the tangential loading on the rotor blade.

Each rotor blade has a rotational twist mechanism, either passive or dynamic built into the root of the blade, producing a uniform incremental pitch control along its length (constant twist). The amount of pitch required is only a few degrees as small changes in the pitch angle can have a dramatic effect on the power output as we know from the previous tutorial that the energy contained in the wind is proportional to the cube of the wind speed.

One of the major advantages of rotor blade pitch control is the increase in the wind speed window. A positive pitch angle produces a large starting torque as the rotor begins to turn decreasing its cut-in wind speed. Likewise, in high wind speeds when the rotors maximum speed limit is reached, the pitch can be controlled to keep the rotors rpm from exceeding its limit by reducing their efficiency and angle of attack.

Power regulation of a wind turbine can be achieved by using pitch control on the rotor blades to either reduce or increase the lift force on the blades by controlling the angle of attack. Smaller rotor blades achieve this by incorporating a small twist in their design. Larger commercial wind turbines use pitch control either passive, with the aid of centrifugal springs and levers (similar to helicopter rotors) or by active using small electrical motors built into the blades hub to rotate it the required few degrees. The principal disadvantages of pitch control are reliability and cost.

• Blade Construction – the kinetic energy extracted from the wind is influenced by the geometry of the rotor blades and determining the aerodynamically optimum blade shape and design is important. But as well as the aerodynamic design of the rotor blade the structural design is equally important. The structural design consists of blade material selection and strength as the blades flex and bend by the winds energy while they rotate.

Obviously, the ideal constructional material for a rotor blade would combine the necessary structural properties of high strength to weight ratio, high fatigue life, stiffness, its natural vibration frequency and resistance to fatigue along with low cost and the ability to be easily formed into the desired aerofoil shape.

The rotor blades of smaller turbines used in residential applications that range in size from 100 watts and upwards are generally made of solid carved wood, wood laminates or wood veneer composites as well as aluminium or steel. Wooden rotor blades are strong, light weight, cheap, flexible and popular with most do-it-yourself wind turbine designs as they can be easily made. However, the low strength of wood laminates compared with other wood materials renders it unsuitable for blades with slender designs operating at high tip speeds.

Aluminium blades are also light weight, strong and easy to work with, but are more expensive, easily bent and suffer from metal fatigue. Likewise steel blades uses the cheapest material and can be formed and shaped into curved panels following the required aerofoil profile. However, it is much harder to introduce a twist into steel panels, and together with poor fatigue properties, meaning it rusts, means that steel is rarely used.

The rotor blades used for very large horizontal axis wind turbine design are made from reinforced plastic composites with the most common composites consisting of fibreglass/polyester resin, fibreglass/epoxy, fibreglass/polyester and carbon-fibre composites. Glass-fibre and carbon-fibre composites have a substantially higher compressive strength-to-weight ratio compared with the other materials. Also, fibreglass is lightweight, strong, inexpensive, has good fatigue characteristics and can be used in a variety of manufacturing processes.

The size, type and construction of the wind turbine you may need depends on your particular application and power requirements. Small wind turbine designs range in size from 20 watts to 50 kilowatts (kW) with smaller or “micro” (20- to 500-watt) turbines be used in residential locations for a variety of applications such electrical power generation for charging batteries and powering lights.

Wind energy is among the world’s fastest-growing sources of renewable energy as it is a clean, widely distributed energy resource that is abundant, has zero fuel cost, emissions-free power generation technology. Most modern wind turbine generators available today are designed to be installed and used in residential type installations.

As a result, they are manufactured smaller and more lightweight allowing them to be quickly and easily mounted directly onto a roof or onto a short pole or tower. Installing a newer turbine generator as part of your home wind power system will allow you to reduce most of the higher costs of maintaining and installing a taller and more expensive turbine tower as you would have before in the past.

In the next tutorial about Wind Energy, we will look at the operation and design of wind turbine generators used for generating electricity as part of a home based wind turbine generating system.

Wind turbine design is the process of defining the form and specifications of a wind turbine to extract energy from the wind.[1] [2] A wind turbine installation consists of the necessary systems needed to capture the wind's energy, point the turbine into the wind, convert mechanical rotation into electrical power, and other systems to start, stop, and control the turbine.

This article covers the design of horizontal axis wind turbines (HAWT) since the majority of commercial turbines use this design.

In 1919, the physicist Albert Betz showed that for a hypothetical ideal wind-energy extraction machine, the fundamental laws of conservation of mass and energy allowed no more than 16/27 (59.3%) of the kinetic energy of the wind to be captured. This Betz' law limit can be approached by modern turbine designs which may reach 70 to 80% of this theoretical limit.

In addition to aerodynamic design of the blades, design of a complete wind power system must also address design of the hub, controls, generator, supporting structure and foundation. Further design questions arise when integrating wind turbines into electrical power grids.

Aerodynamics

The shape and dimensions of the blades of the wind turbine are determined by the aerodynamic performance required to efficiently extract energy from the wind, and by the strength required to resist the forces on the blade.

The aerodynamics of a horizontal-axis wind turbine are not straightforward. The air flow at the blades is not the same as the airflow far away from the turbine. The very nature of the way in which energy is extracted from the air also causes air to be deflected by the turbine. In addition the aerodynamics of a wind turbine at the rotor surface exhibit phenomena that are rarely seen in other aerodynamic fields.

In 1919, the physicist Albert Betz showed that for a hypothetical ideal wind-energy extraction machine, the fundamental laws of conservation of mass and energy allowed no more than 16/27 (59.3%) of the kinetic energy of the wind to be captured. This Betz' law limit can be approached by modern turbine designs which may reach 70 to 80% of this theoretical limit.

Power control

The speed at which a wind turbine rotates must be controlled for efficient power generation and to keep the turbine components within designed speed and torque limits. The centrifugal force on the spinning blades increases as the square of the rotation speed, which makes this structure sensitive to overspeed. Because the power of the wind increases as the cube of the wind speed, turbines have to be built to survive much higher wind loads (such as gusts of wind) than those from which they can practically generate power. Wind turbines have ways of reducing torque in high winds.

A wind turbine is designed to produce power over a range of wind speeds. The cut-in speed is around 3–4 m/s for most turbines, and cut-out at 25 m/s.[3] If the rated wind speed is exceeded the power has to be limited. There are various ways to achieve this.

A control system involves three basic elements: sensors to measure process variables, actuators to manipulate energy capture and component loading, and control algorithms to coordinate the actuators based on information gathered by the sensors.[4]

All wind turbines are designed for a maximum wind speed, called the survival speed, above which they will be damaged. The survival speed of commercial wind turbines is in the range of 40 m/s (144 km/h, 89 MPH) to 72 m/s (259 km/h, 161 MPH). The most common survival speed is 60 m/s (216 km/h, 134 MPH). Some have been designed to survive 80 metres per second (290 km/h; 180 mph).[5]

Stall

Stalling works by increasing the angle at which the relative wind strikes the blades (angle of attack), and it reduces the induced drag (drag associated with lift). Stalling is simple because it can be made to happen passively (it increases automatically when the winds speed up), but it increases the cross-section of the blade face-on to the wind, and thus the ordinary drag. A fully stalled turbine blade, when stopped, has the flat side of the blade facing directly into the wind.

A fixed-speed HAWT (Horizontal Axis Wind Turbine) inherently increases its angle of attack at higher wind speed as the blades speed up. A natural strategy, then, is to allow the blade to stall when the wind speed increases. This technique was successfully used on many early HAWTs. However, on some of these blade sets, it was observed that the degree of blade pitch tended to increase audible noise levels.

Vortex generators may be used to control the lift characteristics of the blade. The VGs are placed on the airfoil to enhance the lift if they are placed on the lower (flatter) surface or limit the maximum lift if placed on the upper (higher camber) surface.[6]

Furling

Furling works by decreasing the angle of attack, which reduces the induced drag from the lift of the rotor, as well as the cross-section. One major problem in designing wind turbines is getting the blades to stall or furl quickly enough should a gust of wind cause sudden acceleration. A fully furled turbine blade, when stopped, has the edge of the blade facing into the wind.

Loads can be reduced by making a structural system softer or more flexible.[4] This could be accomplished with downwind rotors or with curved blades that twist naturally to reduce angle of attack at higher wind speeds. These systems will be nonlinear and will couple the structure to the flow field - thus, design tools must evolve to model these nonlinearities.

Standard modern turbines all furl the blades in high winds. Since furling requires acting against the torque on the blade, it requires some form of pitch angle control, which is achieved with a slewing drive. This drive precisely angles the blade while withstanding high torque loads. In addition, many turbines use hydraulic systems. These systems are usually spring-loaded, so that if hydraulic power fails, the blades automatically furl. Other turbines use an electric servomotor for every rotor blade. They have a small battery-reserve in case of an electric-grid breakdown. Small wind turbines (under 50 kW) with variable-pitching generally use systems operated by centrifugal force, either by flyweights or geometric design, and employ no electric or hydraulic controls.

Fundamental gaps exist in pitch control, limiting the reduction of energy costs, according to a report from a coalition of researchers from universities, industry, and government, supported by the Atkinson Center for a Sustainable Future. Load reduction is currently focused on full-span blade pitch control, since individual pitch motors are the actuators currently available on commercial turbines. Significant load mitigation has been demonstrated in simulations for blades, tower, and drive train. However, there is still research needed, the methods for realization of full-span blade pitch control need to be developed in order to increase energy capture and mitigate fatigue loads.

A control technique applied to the pitch angle is done by comparing the current active power of the engine with the value of active power at the rated engine speed (active power reference, Ps reference). Control of the pitch angle in this case is done with a PI controller controls. However, in order to have a realistic response to the control system of the pitch angle, the actuator uses the time constant Tservo, an integrator and limiters so as the pitch angle to be from 0° to 30° with a rate of change (± 10° per sec).

From the figure at the right, the reference pitch angle is compared with the actual pitch angle b and then the error is corrected by the actuator. The reference pitch angle, which comes from the PI controller, goes through a limiter. Restrictions on limits are very important to maintain the pitch angle in real term. Limiting the rate of change is very important especially during faults in the network. The importance is due to the fact that the controller decides how quickly it can reduce the aerodynamic energy to avoid acceleration during errors.[4]

Other controls

Generator torque

Modern large wind turbines are variable-speed machines. When the wind speed is below rated, generator torque is used to control the rotor speed in order to capture as much power as possible. The most power is captured when the tip speed ratio is held constant at its optimum value (typically 6 or 7). This means that as wind speed increases, rotor speed should increase proportionally. The difference between the aerodynamic torque captured by the blades and the applied generator torque controls the rotor speed. If the generator torque is lower, the rotor accelerates, and if the generator torque is higher, the rotor slows down. Below rated wind speed, the generator torque control is active while the blade pitch is typically held at the constant angle that captures the most power, fairly flat to the wind. Above rated wind speed, the generator torque is typically held constant while the blade pitch is active.

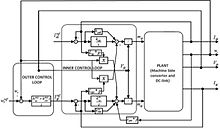

One technique to control a permanent magnet synchronous motor is Field Oriented Control. Field Oriented Control is a closed loop strategy composed of two current controllers (an inner loop and outer loop cascade design) necessary for controlling the torque, and one speed controller.

Constant torque angle control

In this control strategy the d axis current is kept zero, while the vector current is align with the q axis in order to maintain the torque angle equal with 90o. This is one of the most used control strategy because of the simplicity, by controlling only the Iqs current. So, now the electromagnetic torque equation of the permanent magnet synchronous generator is simply a linear equation depend on the Iqs current only.

So, the electromagnetic torque for Ids = 0 (we can achieve that with the d-axis controller) is now:

Te= 3/2 p (λpm Iqs + (Lds-Lqs) Ids Iqs )= 3/2 p λpm Iqs

So, the complete system of the machine side converter and the cascaded PI controller loops is given by the figure in the right. In that we have the control inputs, which are the duty rations mds and mqs, of the PWM-regulated converter. Also, we can see the control scheme for the wind turbine in the machine side and simultaneously how we keep the Ids zero (the electromagnetic torque equation is linear).

Yawing

Modern large wind turbines are typically actively controlled to face the wind direction measured by a wind vane situated on the back of the nacelle. By minimizing the yaw angle (the misalignment between wind and turbine pointing direction), the power output is maximized and non-symmetrical loads minimized. However, since the wind direction varies quickly the turbine will not strictly follow the direction and will have a small yaw angle on average. The power output losses can simply be approximated to fall with (cos(yaw angle))3. Particularly at low-to-medium wind speeds, yawing can make a significant reduction in turbine output, with wind direction variations of ±30° being quite common and long response times of the turbines to changes in wind direction. At high wind speeds, the wind direction is less variable.

Electrical braking

Braking of a small wind turbine can be done by dumping energy from the generator into a resistor bank, converting the kinetic energy of the turbine rotation into heat. This method is useful if the kinetic load on the generator is suddenly reduced or is too small to keep the turbine speed within its allowed limit.

Cyclically braking causes the blades to slow down, which increases the stalling effect, reducing the efficiency of the blades. This way, the turbine's rotation can be kept at a safe speed in faster winds while maintaining (nominal) power output. This method is usually not applied on large grid-connected wind turbines.

Mechanical braking

A mechanical drum brake or disk brake is used to stop turbine in emergency situation such as extreme gust events or over speed. This brake is a secondary means to hold the turbine at rest for maintenance, with a rotor lock system as primary means. Such brakes are usually applied only after blade furling and electromagnetic braking have reduced the turbine speed generally 1 or 2 rotor RPM, as the mechanical brakes can create a fire inside the nacelle if used to stop the turbine from full speed. The load on the turbine increases if the brake is applied at rated RPM. Mechanical brakes are driven by hydraulic systems and are connected to main control box.

Turbine size

There are different size classes of wind turbines. The smallest having power production less than 10 kW are used in homes, farms and remote applications whereas intermediate wind turbines (10-250 kW ) are useful for village power, hybrid systems and distributed power. The world's largest wind turbine, an 8-MW turbine located at the Burbo Bank Extension wind farm in Liverpool Bay, United Kingdom, was installed in 2016.[7] Utility-scale turbines (larger than one megawatt) are used in central station wind farms, distributed power and community wind.[8]

For a given survivable wind speed, the mass of a turbine is approximately proportional to the cube of its blade-length. Wind power intercepted by the turbine is proportional to the square of its blade-length.[9] The maximum blade-length of a turbine is limited by both the strength, the stiffness of its material, and transportation considerations.

Labor and maintenance costs increase only gradually with increasing turbine size, so to minimize costs, wind farm turbines are basically limited by the strength of materials, and siting requirements.

Typical modern wind turbines have diameters of 40 to 90 metres (130 to 300 ft) and are rated between 500 kW and 2 MW. As of 2017 the most powerful turbine, the Vestas V-164, is rated at 9.5 MW and has a rotor diameter of 164m.[10]

Increasingly large wind turbines are being designed, manufacturers have not yet come close to the maximum size. The largest turbines are or will be as big as skyscrapers.[11]

Nacelle

The nacelle is housing the gearbox and generator connecting the tower and rotor. Sensors detect the wind speed and direction, and motors turn the nacelle into the wind to maximize output.

Gearbox

In conventional wind turbines, the blades spin a shaft that is connected through a gearbox to the generator. The gearbox converts the turning speed of the blades 15 to 20 rotations per minute for a large, one-megawatt turbine into the faster 1,800 revolutions per minute that the generator needs to generate electricity.[12] Analysts from GlobalData estimate that gearbox market grows from $3.2bn in 2006 to $6.9bn in 2011, and to $8.1bn by 2020. Market leaders were Winergy in 2011.[13] The use of magnetic gearboxes has also been explored as a way of reducing wind turbine maintenance costs.[14]

Generator

For large, commercial size horizontal-axis wind turbines, the electrical generator[15] is mounted in a nacelle at the top of a tower, behind the hub of the turbine rotor. Typically wind turbines generate electricity through asynchronous machines that are directly connected with the electricity grid. Usually the rotational speed of the wind turbine is slower than the equivalent rotation speed of the electrical network: typical rotation speeds for wind generators are 5–20 rpm while a directly connected machine will have an electrical speed between 750 and 3600 rpm. Therefore, a gearbox is inserted between the rotor hub and the generator. This also reduces the generator cost and weight. Commercial size generators have a rotor carrying a field winding so that a rotating magnetic field is produced inside a set of windings called the stator. While the rotating field winding consumes a fraction of a percent of the generator output, adjustment of the field current allows good control over the generator output voltage.

Older style wind generators rotate at a constant speed, to match power line frequency, which allowed the use of less costly induction generators.[citation needed] Newer wind turbines often turn at whatever speed generates electricity most efficiently. The varying output frequency and voltage can be matched to the fixed values of the grid using multiple technologies such as doubly fed induction generators or full-effect converters where the variable frequency current produced is converted to DC and then back to AC. Although such alternatives require costly equipment and cause power loss, the turbine can capture a significantly larger fraction of the wind energy. In some cases, especially when turbines are sited offshore, the DC energy will be transmitted from the turbine to a central (onshore) inverter for connection to the grid.

Gearless wind turbine

Gearless wind turbines (also called direct drive) get rid of the gearbox completely. Instead, the rotor shaft is attached directly to the generator, which spins at the same speed as the blades.

Advantages of PMDD generators over gear-based generators include increased efficiency, reduced noise, longer lifetime, high torque at low rpm, faster and precise positioning, and drive stiffness. [16] PMDD generators "eliminate the gear-speed increaser, which is susceptible to significant accumulated fatigue torque loading, related reliability issues, and maintenance costs."[17]

To make up for a direct drive generator's slower spinning rate, the diameter of the generator's rotor is increased so that it can contain more magnets to create the required frequency and power. Gearless wind turbines are often heavier than gear-based wind turbines. A study by the EU called "Reliawind"[18] based on the largest sample size of turbines has shown that the reliability of gearboxes is not the main problem in wind turbines. The reliability of direct drive turbines offshore is still not known, since the sample size is so small.

Experts from Technical University of Denmark estimate that a geared generator with permanent magnets may use 25 kg/MW of the rare-earth element Neodymium, while a gearless may use 250 kg/MW.[19]

In December 2011, the US Department of Energy published a report stating critical shortage of rare-earth elements such as neodymium used in large quantities for permanent magnets in gearless wind turbines.[20] China produces more than 95% of rare-earth elements, while Hitachi holds more than 600 patents covering Neodymium magnets. Direct-drive turbines require 600 kg of permanent magnet material per megawatt, which translates to several hundred kilograms of rare-earth content per megawatt, as neodymium content is estimated to be 31% of magnet weight. Hybrid drivetrains (intermediate between direct drive and traditional geared) use significantly less rare-earth materials. While permanent magnet wind turbines only account for about 5% of the market outside of China, their market share inside of China is estimated at 25% or higher. In 2011, demand for neodymium in wind turbines was estimated to be 1/5 of that in electric vehicles.[20]

Blades

Blade design

The ratio between the speed of the blade tips and the speed of the wind is called tip speed ratio. High efficiency 3-blade-turbines have tip speed/wind speed ratios of 6 to 7. Modern wind turbines are designed to spin at varying speeds (a consequence of their generator design, see above). Use of aluminum and composite materials in their blades has contributed to low rotational inertia, which means that newer wind turbines can accelerate quickly if the winds pick up, keeping the tip speed ratio more nearly constant. Operating closer to their optimal tip speed ratio during energetic gusts of wind allows wind turbines to improve energy capture from sudden gusts that are typical in urban settings.

In contrast, older style wind turbines were designed with heavier steel blades, which have higher inertia, and rotated at speeds governed by the AC frequency of the power lines. The high inertia buffered the changes in rotation speed and thus made power output more stable.

It is generally understood that noise increases with higher blade tip speeds. To increase tip speed without increasing noise would allow reduction the torque into the gearbox and generator and reduce overall structural loads, thereby reducing cost.[4] The reduction of noise is linked to the detailed aerodynamics of the blades, especially factors that reduce abrupt stalling. The inability to predict stall restricts the development of aggressive aerodynamic concepts.[4] Some blades (mostly on Enercon) have a winglet to increase performance and/or reduce noise.[21][22]

A blade can have a lift-to-drag ratio of 120,[23] compared to 70 for a sailplane and 15 for an airliner.[24]

The hub

In simple designs, the blades are directly bolted to the hub and are unable to pitch, which leads to aerodynamic stall above certain windspeeds. In other more sophisticated designs, they are bolted to the pitch bearing, which adjusts their angle of attack with the help of a pitch system according to the wind speed to control their rotational speed.[25] The pitch bearing is itself bolted to the hub. The hub is fixed to the rotor shaft which drives the generator directly or through a gearbox.

Blade count

This section includes a list of references, related reading or external links, but its sources remain unclear because it lacks inline citations. (August 2012) (Learn how and when to remove this template message) |

The number of blades is selected for aerodynamic efficiency, component costs, and system reliability. Noise emissions are affected by the location of the blades upwind or downwind of the tower and the speed of the rotor. Given that the noise emissions from the blades' trailing edges and tips vary by the 5th power of blade speed, a small increase in tip speed can make a large difference.

Wind turbines developed over the last 50 years have almost universally used either two or three blades. However, there are patents that present designs with additional blades, such as Chan Shin's Multi-unit rotor blade system integrated wind turbine.[26] Aerodynamic efficiency increases with number of blades but with diminishing return. Increasing the number of blades from one to two yields a six percent increase in aerodynamic efficiency, whereas increasing the blade count from two to three yields only an additional three percent in efficiency.[27] Further increasing the blade count yields minimal improvements in aerodynamic efficiency and sacrifices too much in blade stiffness as the blades become thinner.[citation needed]

Theoretically, an infinite number of blades of zero width is the most efficient, operating at a high value of the tip speed ratio. But other considerations lead to a compromise of only a few blades.[28]

Component costs that are affected by blade count are primarily for materials and manufacturing of the turbine rotor and drive train. Generally, the lower the number of blades, the lower the material and manufacturing costs will be. In addition, the lower the number of blades, the higher the rotational speed can be. This is because blade stiffness requirements to avoid interference with the tower limit how thin the blades can be manufactured, but only for upwind machines; deflection of blades in a downwind machine results in increased tower clearance. Fewer blades with higher rotational speeds reduce peak torques in the drive train, resulting in lower gearbox and generator costs.

System reliability is affected by blade count primarily through the dynamic loading of the rotor into the drive train and tower systems. While aligning the wind turbine to changes in wind direction (yawing), each blade experiences a cyclic load at its root end depending on blade position. This is true of one, two, three blades or more. However, these cyclic loads when combined together at the drive train shaft are symmetrically balanced for three blades, yielding smoother operation during turbine yaw. Turbines with one or two blades can use a pivoting teetered hub to also nearly eliminate the cyclic loads into the drive shaft and system during yawing. A Chinese 3.6 MW two-blade is being tested in Denmark.[29] Mingyang won a bid for 87 MW (29 * 3 MW) two-bladed offshore wind turbines near Zhuhai in 2013.[30][31][32]

Finally, aesthetics can be considered a factor in that some people find that the three-bladed rotor is more pleasing to look at than a one- or two-bladed rotor.

Blade materials

In general, ideal materials should meet the following criteria:

- wide availability and easy processing to reduce cost and maintenance

- low weight or density to reduce gravitational forces

- high strength to withstand strong loading of wind and gravitational force of the blade itself

- high fatigue resistance to withstand cyclic loading

- high stiffness to ensure stability of the optimal shape and orientation of the blade and clearance with the tower

- high fracture toughness

- the ability to withstand environmental impacts such as lightning strikes, humidity, and temperature[33]

This narrows down the list of acceptable materials. Metals would be undesirable because of their vulnerability to fatigue. Ceramics have low fracture toughness, which could result in early blade failure. Traditional polymers are not stiff enough to be useful, and wood has problems with repeatability, especially considering the length of the blade. That leaves fiber-reinforced composites, which have high strength and stiffness and low density, as a very attractive class of materials for the design of wind turbines.[34]

Wood and canvas sails were used on early windmills due to their low price, availability, and ease of manufacture. Smaller blades can be made from light metals such as aluminium. These materials, however, require frequent maintenance. Wood and canvas construction limits the airfoil shape to a flat plate, which has a relatively high ratio of drag to force captured (low aerodynamic efficiency) compared to solid airfoils. Construction of solid airfoil designs requires inflexible materials such as metals or composites. Some blades also have incorporated lightning conductors.

New wind turbine designs push power generation from the single megawatt range to upwards of 10 megawatts using larger and larger blades. A larger area effectively increases the tip-speed ratio of a turbine at a given wind speed, thus increasing its energy extraction.[35] Computer-aided engineering software such as HyperSizer (originally developed for spacecraft design) can be used to improve blade design.[36][37]

As of 2015 the rotor diameters of onshore wind turbine blades are as large as 130 meters,[38] while the diameter of offshore turbines reach 170 meters.[39] In 2001, an estimated 50 million kilograms of fibreglass laminate were used in wind turbine blades.[40]

An important goal of larger blade systems is to control blade weight. Since blade mass scales as the cube of the turbine radius, loading due to gravity constrains systems with larger blades.[41] Gravitational loads include axial and tensile/ compressive loads (top/bottom of rotation) as well as bending (lateral positions). The magnitude of these loads fluctuates cyclically and the edgewise moments (see below) are reversed every 180° of rotation. Typical rotor speeds and design life are ~10 and 20 years, respectively, with the number of lifetime revolutions on the order of 10^8. Considering wind, it is expected that turbine blades go through ~10^9 loading cycles. Wind is another source of rotor blade loading. Lift causes bending in the flapwise direction (out of rotor plane) while air flow around the blade cause edgewise bending (in the rotor plane). Flapwise bending involves tension on the pressure (upwind) side and compression on the suction (downwind) side. Edgewise bending involves tension on the leading edge and compression on the trailing edge.

Wind loads are cyclical because of natural variability in wind speed and wind shear (higher speeds at top of rotation).

Failure in ultimate loading of wind-turbine rotor blades exposed to wind and gravity loading is a failure mode that needs to be considered when the rotor blades are designed. The wind speed that causes bending of the rotor blades exhibits a natural variability, and so does the stress response in the rotor blades. Also, the resistance of the rotor blades, in terms of their tensile strengths, exhibits a natural variability.[42]

In light of these failure modes and increasingly larger blade systems, there has been continuous effort toward developing cost-effective materials with higher strength-to-mass ratios. In order to extend the current 20 year lifetime of blades and enable larger area blades to be cost-effective, the design and materials need to be optimized for stiffness, strength, and fatigue resistance.[33]

The majority of current commercialized wind turbine blades are made from fiber-reinforced polymers (FRPs), which are composites consisting of a polymer matrix and fibers. The long fibers provide longitudinal stiffness and strength, and the matrix provides fracture toughness, delamination strength, out-of-plane strength, and stiffness.[33] Material indices based on maximizing power efficiency, and having high fracture toughness, fatigue resistance, and thermal stability, have been shown to be highest for glass and carbon fiber reinforced plastics (GFRPs and CFRPs).[43]

Manufacturing blades in the 40 to 50 metre range involves proven fibreglass composite fabrication techniques. Manufactures such as Nordex SE and GE Wind use an infusion process. Other manufacturers use variations on this technique, some including carbon and wood with fibreglass in an epoxy matrix. Other options include preimpregnated ("prepreg") fibreglass and vacuum-assisted resin transfer molding. Each of these options use a glass-fibre reinforced polymer composite constructed with differing complexity. Perhaps the largest issue with more simplistic, open-mould, wet systems are the emissions associated with the volatile organics released. Preimpregnated materials and resin infusion techniques avoid the release of volatiles by containing all VOCs. However, these contained processes have their own challenges, namely the production of thick laminates necessary for structural components becomes more difficult. As the preform resin permeability dictates the maximum laminate thickness, bleeding is required to eliminate voids and ensure proper resin distribution.[40] One solution to resin distribution a partially preimpregnated fibreglass. During evacuation, the dry fabric provides a path for airflow and, once heat and pressure are applied, resin may flow into the dry region resulting in a thoroughly impregnated laminate structure.[40]

Epoxy-based composites have environmental, production, and cost advantages over other resin systems. Epoxies also allow shorter cure cycles, increased durability, and improved surface finish. Prepreg operations further reduce processing time over wet lay-up systems. As turbine blades pass 60 metres, infusion techniques become more prevalent; the traditional resin transfer moulding injection time is too long as compared to the resin set-up time, limiting laminate thickness. Injection forces resin through a thicker ply stack, thus depositing the resin where in the laminate structure before gelation occurs. Specialized epoxy resins have been developed to customize lifetimes and viscosity.[45]

Carbon fibre-reinforced load-bearing spars can reduce weight and increase stiffness. Using carbon fibres in 60 metre turbine blades is estimated to reduce total blade mass by 38% and decrease cost by 14% compared to 100% fibreglass. Carbon fibres have the added benefit of reducing the thickness of fiberglass laminate sections, further addressing the problems associated with resin wetting of thick lay-up sections. Wind turbines may also benefit from the general trend of increasing use and decreasing cost of carbon fibre materials.[40]

Although glass and carbon fibers have many optimal qualities for turbine blade performance, there are several downsides to these current fillers, including the fact that high filler fraction (10-70 wt%) causes increased density as well as microscopic defects and voids that often lead to premature failure.[33]

Recent developments include interest in using carbon nanotubes (CNTs) to reinforce polymer-based nanocomposites. CNTs can be grown or deposited on the fibers, or added into polymer resins as a matrix for FRP structures. Using nanoscale CNTs as filler instead of traditional microscale filler (such as glass or carbon fibers) results in CNT/polymer nanocomposites, for which the properties can be changed significantly at very low filler contents (typically < 5 wt%). They have very low density, and improve the elastic modulus, strength, and fracture toughness of the polymer matrix. The addition of CNTs to the matrix also reduces the propagation of interlaminar cracks which can be a problem in traditional FRPs.[33]

Further improvement is possible through the use of carbon nanofibers (CNFs) in the blade coatings. A major problem in desert environments is erosion of the leading edges of blades by wind carrying sand, which increases roughness and decreases aerodynamic performance. The particle erosion resistance of fiber-reinforced polymers is poor when compared to metallic materials and elastomers, and needs to be improved. It has been shown that the replacement of glass fiber with CNF on the composite surface greatly improves erosion resistance. CNFs have also been shown to provide good electrical conductivity (important for lightning strikes), high damping ratio, and good impact-friction resistance. These properties make CNF-based nanopaper a prospective coating for wind turbine blades.[46][47]

Another important source of degradation for turbine blades is lightning damage, which over the course of a normal 25-year lifetime is expected to experience a number of lightning strikes throughout its service.[48] The range of damage caused from lightning strikes goes from merely surface level scorching and cracking of the laminate material, to ruptures in the blade or full separation in the adhesives that hold the blade together.[48]It is most common to observe lightning strikes on the tips of the blades, especially in rainy weather due to the copper wiring within attracting lightning.[49] The most common method to combat this, especially in non-conducting blade materials like GFRPs and CFRPs, is to add lightning "arresters", which are merely metallic wiring that provides an uninterrupted path to the ground, skipping the blades and gearbox entirely to eliminate the risk of damage in those components.[49]

Blade recycling

The Global Wind Energy Council (GWEC) predicts that wind energy will supply 15.7% of the world’s total energy needs by the year 2020, and 28.5% by the year 2030.[50] This dramatic increase in global wind energy generation will require installation of a newer and larger fleet of more efficient wind turbines and the consequent decommissioning of aging ones. Based on a study carried out by the European Wind Energy Association, in the year 2010 alone, between 110 and 140 kilotons of composites were consumed by the wind turbine industry for manufacturing blades.[51] The majority of the blade material will eventually end up as waste, and in order to accommodate this level of composite waste, the only option is recycling. Typically, glass-fibre-reinforced-polymers (GFRPs) compose of around 70% of the laminate material in the blade. GFRPs hinder incineration and are not combustible.[52] Therefore, conventional recycling methods need to be modified. Currently, depending on whether individual fibres can be recovered, there exists a few general methods for recycling GFRPs in wind turbine blades:

- Mechanical Recycling: This method doesn't recover individual fibres. Initial processes involve shredding, crushing, and/or milling. The crushed pieces are then separated into fibre-rich and resin-rich fractions. These fractions are ultimately incorporated into new composites either as fillers or reinforcements.[53]

- Chemical Processing/Pyrolysis: Thermal decomposition of the composites is used to recover the individual fibres. For pyrolysis, the material is heated up to 500 °C in an environment without oxygen, thus causing it to break down into lower weight organic substances and/or gaseous products. The glass fibres will generally lose 50% of their initial strength and can now be downcycled for fibre reinforcement applications in paints or concrete.[54] Research has shown that this end of life option is able to recover up to approximately 19 MJ/kg.[55] However, this method has a relatively high cost and requires similar mechanical pre-processing. In addition, it has not yet been modified to satisfy the future need of large scale wind turbine blade recycling.[56]

- Direct Structural recycling of composites: Developed to combat the inefficiencies and costs associated with chemical, thermal and mechanical recycling processes, which either reduce the performance properties or only act as filler for other composites. The general idea to this method is to reuse the composite as is, which can be achieved especially in larger composite materials as it can be partitioned in several pieces which can be used in other applications as is, without altering the chemical properties of the composite component. [57]

Tower

Tower height

Wind velocities increase at higher altitudes due to surface aerodynamic drag (by land or water surfaces) and the viscosity of the air. The variation in velocity with altitude, called wind shear, is most dramatic near the surface. Typically, the variation follows the wind profile power law, which predicts that wind speed rises proportionally to the seventh root of altitude. Doubling the altitude of a turbine, then, increases the expected wind speeds by 10% and the expected power by 34%. To avoid buckling, doubling the tower height generally requires doubling the diameter of the tower as well, increasing the amount of material by a factor of at least four.

At night time, or when the atmosphere becomes stable, wind speed close to the ground usually subsides whereas at turbine hub altitude it does not decrease that much or may even increase. As a result, the wind speed is higher and a turbine will produce more power than expected from the 1/7 power law: doubling the altitude may increase wind speed by 20% to 60%. A stable atmosphere is caused by radiative cooling of the surface and is common in a temperate climate: it usually occurs when there is a (partly) clear sky at night. When the (high altitude) wind is strong (a 10-meter wind speed higher than approximately 6 to 7 m/s) the stable atmosphere is disrupted because of friction turbulence and the atmosphere will turn neutral. A daytime atmosphere is either neutral (no net radiation; usually with strong winds and heavy clouding) or unstable (rising air because of ground heating—by the sun). Here again the 1/7 power law applies or is at least a good approximation of the wind profile. Indiana had been rated as having a wind capacity of 30,000 MW, but by raising the expected turbine height from 50 m to 70 m, the wind capacity estimate was raised to 40,000 MW, and could be double that at 100 m.[58]

For HAWTs, tower heights approximately two to three times the blade length have been found to balance material costs of the tower against better utilisation of the more expensive active components.

Road size restrictions makes transportation of towers with a diameter of more than 4.3 m difficult. Swedish analyses show that it is important to have the bottom wing tip at least 30 m above the tree tops, but a taller tower requires a larger tower diameter.[59] A 3 MW turbine may increase output from 5,000 MWh to 7,700 MWh per year by going from 80 to 125 meter tower height.[60] A tower profile made of connected shells rather than cylinders can have a larger diameter and still be transportable. A 100 m prototype tower with TC bolted 18 mm 'plank' shells has been erected at the wind turbine test center Høvsøre in Denmark and certified by Det Norske Veritas, with a Siemens nacelle. Shell elements can be shipped in standard 12 m shipping containers,[59][61] and 2½ towers per week are produced this way.[62]

As of 2003, typical modern wind turbine installations use towers about 210 ft (65 m) high. Height is typically limited by the availability of cranes. This has led to a variety of proposals for "partially self-erecting wind turbines" that, for a given available crane, allow taller towers that put a turbine in stronger and steadier winds, and "self-erecting wind turbines" that can be installed without cranes.[63][64][65][66]

Tower materials

Currently, the majority of wind turbines are supported by conical tubular steel towers. These towers represent 30% – 65% of the turbine weight and therefore account for a large percentage of the turbine transportation costs. The use of lighter materials in the tower could greatly reduce the overall transport and construction cost of wind turbines, however the stability must be maintained.[67] Higher grade S500 steel costs 20%-25% more than S335 steel (standard structural steel), but it requires 30% less material because of its improved strength. Therefore, replacing wind turbine towers with S500 steel would result in net savings both in weight and cost.[68]

Another disadvantage of conical steel towers is that constructing towers that meet the requirements of wind turbines taller than 90 meters proves challenging. High performance concrete shows potential to increase tower height and increase the lifetime of the towers. A hybrid of prestressed concrete and steel has shown improved performance over standard tubular steel at tower heights of 120 meters.[69] Concrete also gives the benefit of allowing for small precast sections to be assembled on site, avoiding the challenges steel faces during transportation.[70] One downside of concrete towers is the higher CO2 emissions during concrete production as compared to steel. However, the overall environmental benefit should be higher if concrete towers can double the wind turbine lifetime.[71]

Wood is being investigated as a material for wind turbine towers, and a 100 metre tall tower supporting a 1.5 MW turbine has been erected in Germany. The wood tower shares the same transportation benefits of the segmented steel shell tower, but without the steel resource consumption.[72][73]

Connection to the electric grid

All grid-connected wind turbines, from the first one in 1939 until the development of variable-speed grid-connected wind turbines in the 1970s, were fixed-speed wind turbines. As recently as 2003, nearly all grid-connected wind turbines operated at exactly constant speed (synchronous generators) or within a few percent of constant speed (induction generators).[74][75] As of 2011, many operational wind turbines used fixed speed induction generators (FSIG).[76] As of 2011, most new grid-connected wind turbines are variable speed wind turbines—they are in some variable speed configuration.[76]

Early wind turbine control systems were designed for peak power extraction, also called maximum power point tracking—they attempt to pull the maximum possible electrical power from a given wind turbine under the current wind conditions.[77] More recent wind turbine control systems deliberately pull less electrical power than they possibly could in most circumstances, in order to provide other benefits, which include:

- spinning reserves to quickly produce more power when needed—such as when some other generator suddenly drops from the grid—up to the max power supported by the current wind conditions.[78]

- Variable-speed wind turbines can (very briefly) produce more power than the current wind conditions can support, by storing some wind energy as kinetic energy (accelerating during brief gusts of faster wind) and later converting that kinetic energy to electric energy (decelerating, either when more power is needed elsewhere, or during short lulls in the wind, or both).[79][80]

- damping (electrical) subsynchronous resonances in the grid[81]

- damping (mechanical) resonances in the tower[82][83]

The generator in a wind turbine produces alternating current (AC) electricity. Some turbines drive an AC/AC converter—which converts the AC to direct current (DC) with a rectifier and then back to AC with an inverter—in order to match the frequency and phase of the grid. However, the most common method in large modern turbines is to instead use a doubly fed induction generator directly connected to the electricity grid.

A useful technique to connect a permanent magnet synchronous generator to the grid is by using a back-to-back converter. Also, we can have control schemes so as to achieve unity power factor in the connection to the grid. In that way the wind turbine will not consume reactive power, which is the most common problem with wind turbines that use induction machines. This leads to a more stable power system. Moreover, with different control schemes a wind turbine with a permanent magnet synchronous generator can provide or consume reactive power. So, it can work as a dynamic capacitor/inductor bank so as to help with the power systems' stability.

Below we show the control scheme so as to achieve unity power factor :

Reactive power regulation consists of one PI controller in order to achieve operation with unity power factor (i.e. Qgrid = 0 ). It is obvious that IdN has to be regulated to reach zero at steady-state (IdNref = 0).

We can see the complete system of the grid side converter and the cascaded PI controller loops in the figure in the right.

Foundations

Wind turbines, by their nature, are very tall slender structures,[84] this can cause a number of issues when the structural design of the foundations are considered. The foundations for a conventional engineering structure are designed mainly to transfer the vertical load (dead weight) to the ground, this generally allows for a comparatively unsophisticated arrangement to be used. However, in the case of wind turbines, the force of the wind's interaction with the rotor at the top of the tower creates a strong tendency to tip the wind turbine over. This loading regime causes large moment loads to be applied to the foundations of a wind turbine. As a result, considerable attention needs to be given when designing the footings to ensure that the foundation will resist this tipping tendency.[85]

One of the most common foundations for offshore wind turbines is the monopile, a single large-diameter (4 to 6 metres) tubular steel pile driven to a depth of 5-6 times the diameter of the pile into the seabed. The cohesion of the soil, and friction between the pile and the soil provide the necessary structural support for the wind turbine.[86]

In onshore turbines the most common type of foundation is a gravity foundation, where a large mass of concrete spread out over a large area is used to resist the turbine loads. Wind turbine size & type, wind conditions and soil conditions at the site are all determining factors in the design of the foundation. [87]

Costs

The modern wind turbine is a complex and integrated system. Structural elements comprise the majority of the weight and cost. All parts of the structure must be inexpensive, lightweight, durable, and manufacturable, under variable loading and environmental conditions. Turbine systems that have fewer failures,[90] require less maintenance, are lighter and last longer will lead to reducing the cost of wind energy.

One way to achieve this is to implement well-documented, validated analysis codes, according to a 2011 report from a coalition of researchers from universities, industry, and government, supported by the Atkinson Center for a Sustainable Future.[4]

The major parts of a modern turbine may cost (percentage of total): tower 22%, blades 18%, gearbox 14%, generator 8%.[91][92]

Design specification

The design specification for a wind-turbine will contain a power curve and guaranteed availability. With the data from the wind resource assessment it is possible to calculate commercial viability.[1] The typical operating temperature range is −20 to 40 °C (−4 to 104 °F). In areas with extreme climate (like Inner Mongolia or Rajasthan) specific cold and hot weather versions are required.

Wind turbines can be designed and validated according to IEC 61400 standards.[93]